Mobility Division

At the Mobility Division, we provide, transport, and install various production facilities not only for internal combustion engine (ICE) vehicles, but also for batteries, e-Axles, battery cases, and other key electrified vehicle components, for automotive manufacturers around the world.

We contribute to decarbonization through the sale of equipment and materials used for lithium-ion, solid-state and other rechargeable batteries in electrified vehicles (EVs), for fuel cells, and through initiatives related to Gigacast lines, which reduce both the number and weight of components. We also provide a wide range of solutions that utilize leading-edge technologies, such as supplying and upgrading robot-based automated systems.

Proposals for a wide variety of equipment from Japan and overseas

-

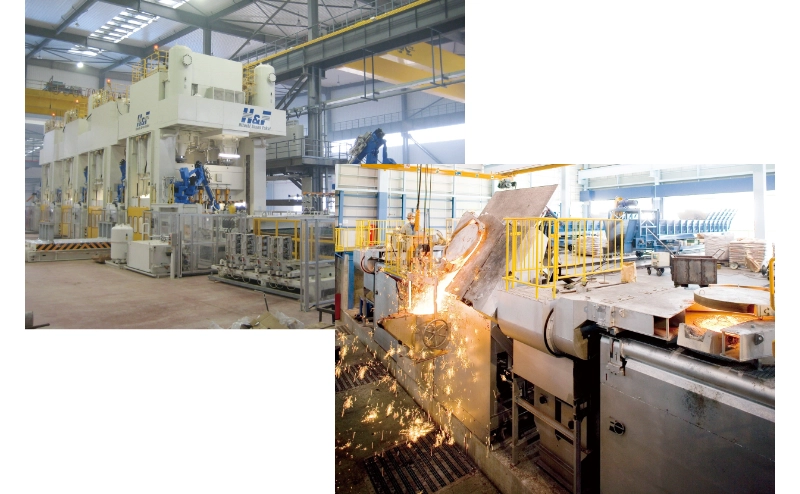

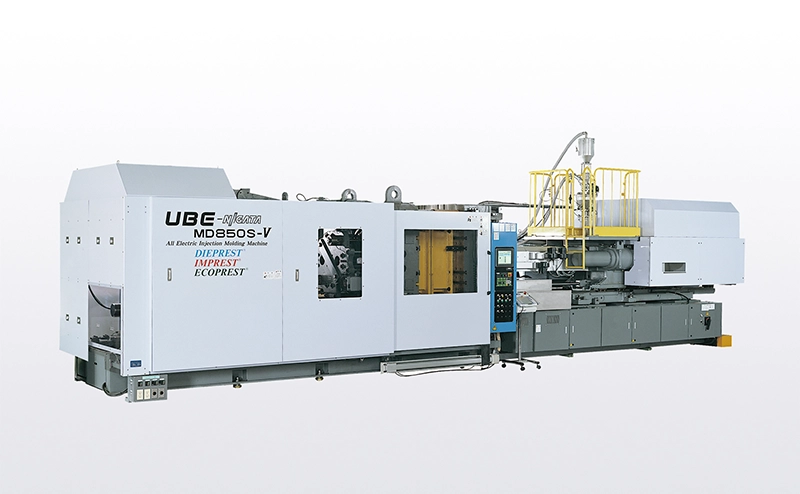

We offer equipment used in many different manufacturing processes involved in the production of automobiles, from the upstream to downstream processes. These processes range from casting, forging, machining, and stamping through to injection molding, painting, and inspections. Through this equipment, we propose optimal solutions to our customers.

-

Tandem press lin(ePhoto:Provided by Hitachi Zosen Fukui Corporation) High frequency induction furnac(ePhoto:Provided by Fuji Electric Co., Ltd.)

-

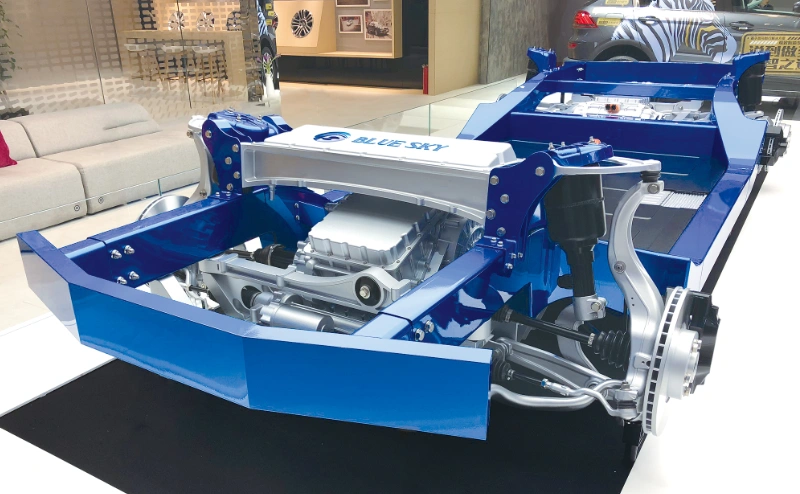

BEV platform

Source: Blue Sky Technology Inc. -

Injection machine

(Photo:Provided by UBE MACHINERY CORPORATION, LTD.)

Ultra-large aluminum parts

Megacast and Gigacast lines

We promote the use of Megacast and Gigacast integrated molding machines for ultra-large aluminum parts, which are gaining traction as next-generation technologies for automotive production. We have been active in the field of aluminum casting from the 1990s, since when we have built up an abundance of knowledge and established a track record of success.

Thanks to our partnerships with Japanese and overseas equipment manufacturers, we are also able to offer comprehensive solutions that incorporate not only Megacast and Gigacast machines but also large-scale molds and peripheral equipment, thereby meeting the needs of customers interested in integrated molding of body parts and other components.

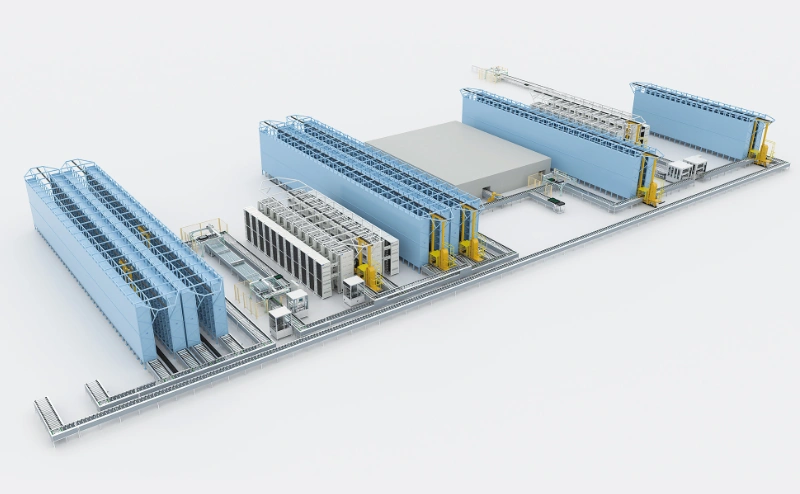

Engineers and technical supervisors on hand to undertake large-scale installation projects

-

-

Complete on-site safety management and process management are needed to complete work within the limited period for equipment installation.

We have in-house technical supervisors that are able to handle large-scale installation projects. Our experienced staff members provide customers with wide range of operation support, from project-related documentation to process management and on-site management.

Engineering, Equipment Procurement, contracting Overseas Installation Work for setting up overseas automobile factories, and providing Maintenance Service

Overseas Automotive Plant Set-up Support:

-

For all overseas projects involving not only conventional ICE vehicles but also all environmentally friendly vehicles—such as BEVs, HVs, PHVs, and FCVs, we collaborate closely with Sojitz’s international offices to deliver comprehensive solutions that span production line engineering, procurement of manufacturing equipment, on-site installation, and production line commissioning support.

Additionally, through optimal logistics arrangements and support for leveraging preferential tariffs under EPA/FTA and similar agreements, we achieve a reduction in overall project costs.

Following line commissioning, we secure a robust, long-term production support framework for overseas automotive equipment by supplying spare parts, collaborating with local engineering firms on equipment maintenance, and executing equipment modifications aligned with new model introductions.

-

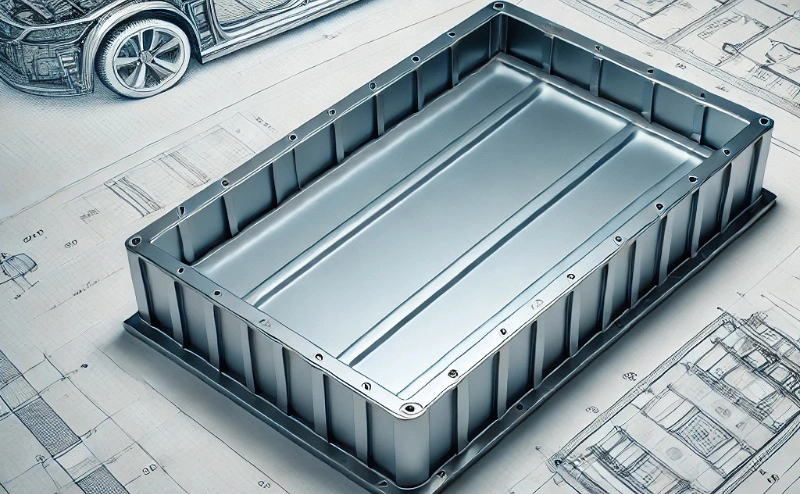

Production of Key Components for EVs

Strengthening the Supply Chain

-

-

Sojitz Machinery plays a pivotal role in enhancing our customers’ competitiveness by providing production readiness support and supplying manufacturing equipment for powertrain components—such as eAxles—used in electric vehicles. In response to the rapidly growing demand for new key components like battery cases driven by electrification trends, we have forged strategic partnerships with both domestic and international suppliers to proactively establish localized production systems that comply with the legal and regulatory requirements of each region.

Furthermore, through our close collaboration with our technical partner, Blue Sky Technology Inc. (BST), in which we hold a capital stake, we deliver cutting-edge electrification technologies and solutions to our customers. BST brings extensive experience and a proven track record in EVs key components, including rechargeable batteries and e-Axles. Leveraging its advanced expertise, BST robustly supports the implementation of optimized production lines and the evaluation of mass-production parts tailored to our customers’ needs. This strategic partnership enables us to provide robust technical support for our customers’ EVs production, bolstering their success in the market.

Through these comprehensive initiatives, we help our customers build a global EVs production infrastructure and secure a competitive edge in the marketplace.

Familiarity with and expertise in EV batteries

Echargeable batteries

-

EV battery cell manufacturing equipment -

Charge/discharge inspection equipment

As society shifts from internal combustion engine vehicles to electrified vehicles, so the automotive battery market continues to grow.

Sojitz Machinery provides Japanese and overseas customers with manufacturing equipment for rechargeable battery for use in HEVs, PHEVs, and BEVs, as well as manufacturing equipment for FCEVs.

We took our first steps in the field of batteries in the beginning of the 1990s, since when we have established a rich track record of success. We currently supply mainly cell assembly process equipment to automobile and battery manufacturers.

In addition to selling battery manufacturing equipment, we also assist with production preparations and offer line engineering proposals.

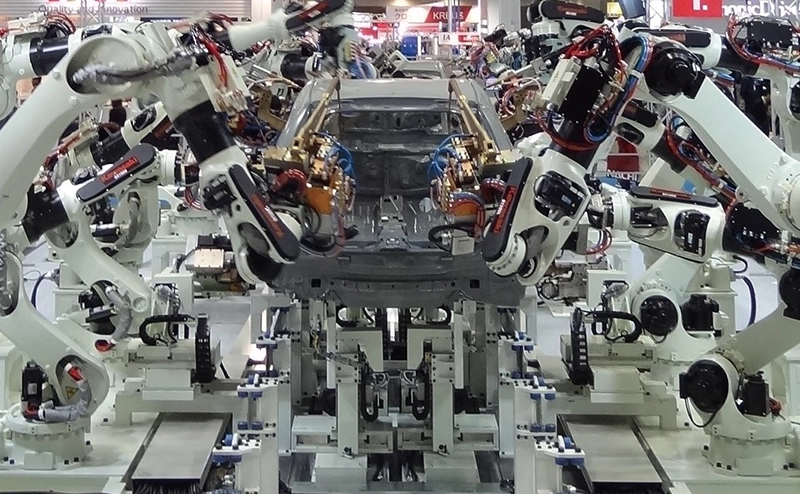

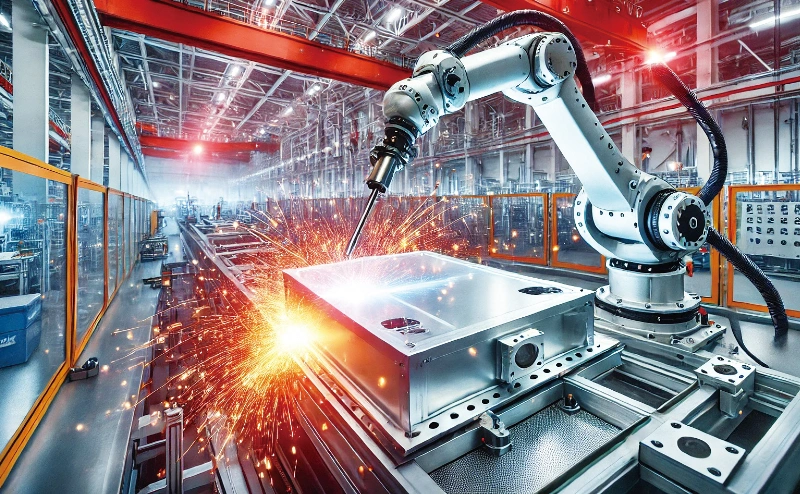

Provision and upgrade of automatedrobot-based systems

Robotics solution services

-

We provide automated production line solutions centered around automobile manufacturers, including painting, welding, and transport systems that have been upgraded with various types of robots for both new facilities and aging machines.

-

duAro collaborative

dual-arm SCARA robotIndustrial Robots (Photo: provided by Kawasaki Heavy Industries, Ltd.)